Excavators are essential machines in construction, mining, agriculture, and landscaping. They come in various types, each designed for specific tasks and site conditions. Understanding the differences between excavator types can help businesses select the right equipment to improve efficiency and reduce operating costs. In this article, we explore the top 5 types of excavators in 2025 and their primary uses.

Crawler excavators are the most common type, equipped with tracks instead of wheels. Their tracked undercarriage provides excellent stability and traction on rough, uneven, or muddy terrain.

Uses:

●Heavy-duty construction projects

●Mining and quarry operations

●Road construction and site preparation

●Demolition tasks with hydraulic attachments

Crawler excavators are ideal for projects where mobility on soft or uneven ground is essential. They range in size from small 1-ton models to massive 90-ton machines.

Wheel excavators have rubber tires instead of tracks, offering faster travel on paved surfaces. They are highly maneuverable in urban or street construction environments.

Uses:

●Urban construction and roadwork

●Utility installation and maintenance

●Landscaping in confined spaces

●Transporting material quickly between sites

Wheel excavators are best suited for areas with firm ground and where speed and mobility are important. Their tires reduce surface damage, making them ideal for city projects.

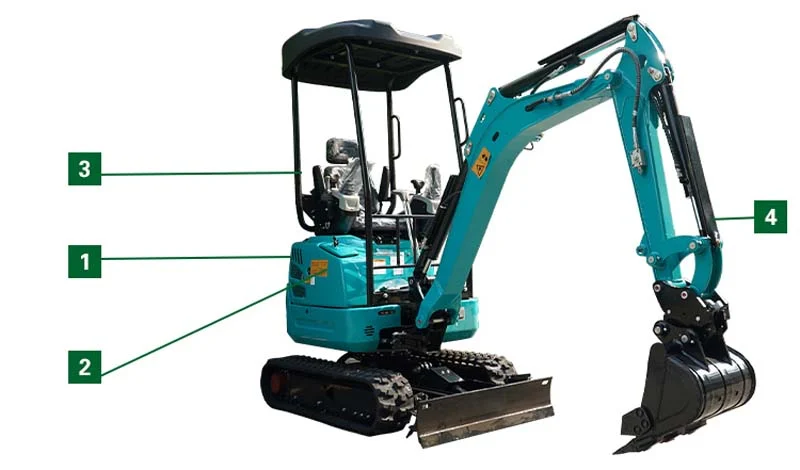

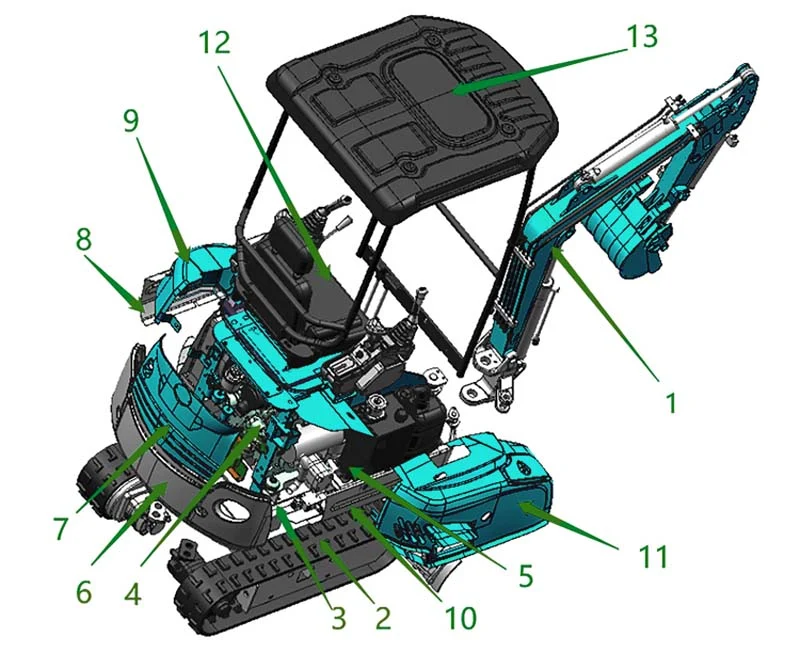

Mini excavators are compact machines weighing between 1 and 8 tons. They are popular due to their versatility, fuel efficiency, and ability to work in tight spaces.

Uses:

●Residential construction

●Landscaping and gardening

●Small-scale utility installation

●Trenching and light demolition

Mini excavators are perfect for contractors who need machines that are easy to transport, operate, and maintain. Their small size allows them to work in confined spaces where larger excavators cannot.

Long reach excavators feature extended arms and booms, allowing them to reach far distances for specialized tasks. They are often used in dredging or demolition work.

Uses:

●River, pond, and canal dredging

●High-rise building demolition

●Deep excavation projects

●Flood control and drainage maintenance

These machines are designed to access areas that standard excavators cannot reach safely, making them indispensable for projects requiring extended reach.

Dragline excavators are large machines with a long boom and suspended bucket. They are mainly used in mining and heavy civil engineering projects.

Uses:

●Open-pit mining and coal excavation

●Large-scale civil construction projects

●Canal and dam excavation

●Bulk material handling in mining

Dragline excavators excel at moving massive amounts of material with minimal operational costs, making them ideal for long-term projects requiring heavy-duty excavation.

Choosing the right type of excavator depends on the project requirements, site conditions, and budget. Crawler excavators are perfect for rough terrain, wheel excavators excel in urban environments, mini excavators are ideal for tight spaces, long reach excavators are suited for extended tasks, and dragline excavators dominate heavy-duty mining operations.

By understanding the strengths and uses of each type, contractors and businesses can improve productivity, reduce operating costs, and select the best excavator for their specific projects.

Tlf: +8615628788742

E-mail: contact02@rippa.com

WhatsApp: Rippa Gravemaskine

Adresse: Den sjette industripark, Jining by, Shandong-provinsen, Kina